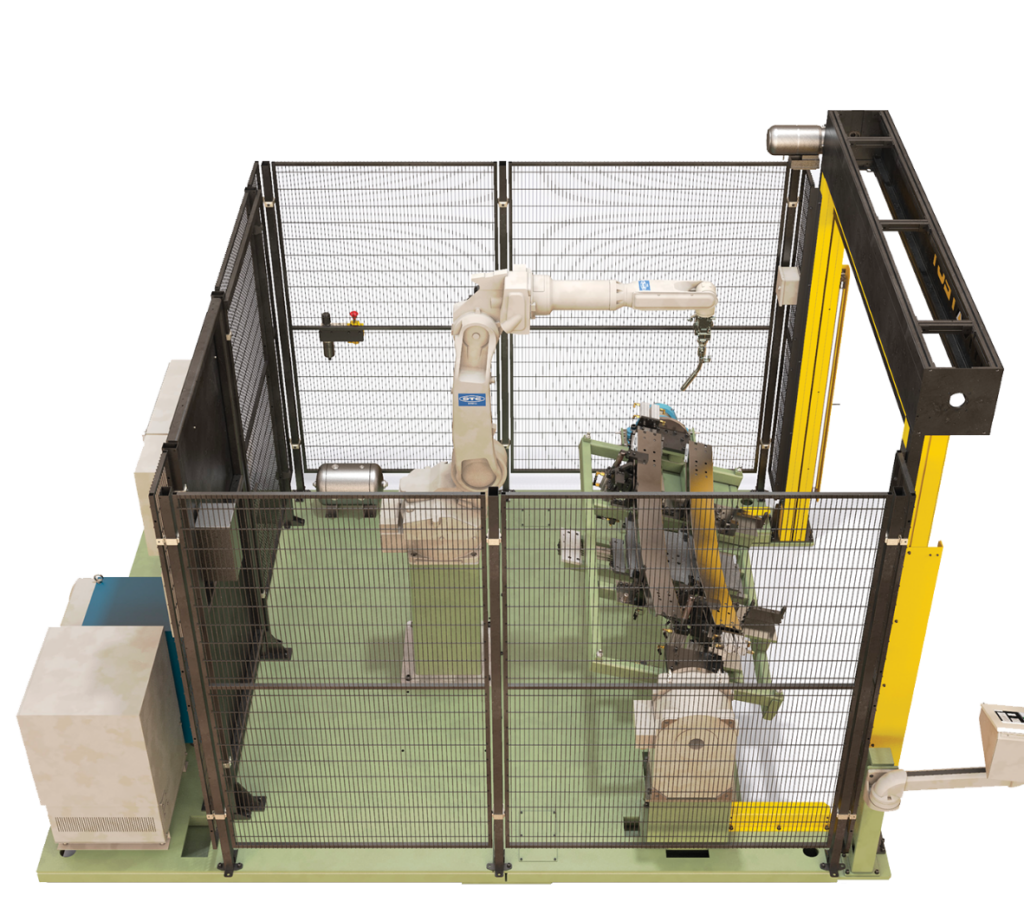

Robotic Welding Systems

A Partner for Better Welding

What would better welding look like for your operations? That’s what Force Design delivers with custom, turnkey, comprehensive automated welding systems.

Automating some or all of your welding processes brings you closer to production goals and solves operational challenges by:

- Boosting throughput

- Opening up production bottlenecks

- Creating more consistent, higher-quality weldments

- Solving welder shortages

- Improving safety and ergonomic conditions

- Putting your skilled welders where they’re needed most

- Enabling you to expand operations, add products, or increase volume

No two products or companies are the same, and that’s why each robotic welding system we design and build is also unique. Our team works with you to understand your materials, up- and downstream processes, worker skill sets, and production challenges. That information guides design and equipment decisions. The result is an efficient welding set up that’s customized to your needs.

What Types of Welding Can Be Automated?

It’s possible to automate most types of welding and most welding applications; however, some may be more practical to implement than others.

A good rule of thumb is to identify components or processes that are error-prone, that take time away from more critical manual welding work, that contribute to bottlenecks, or are simply repetitive and dull for workers. These are often great candidates for robotic welding.

A robotics integrator with specific welding knowledge, like our team, can develop a turnkey welding system for:

Arc welding (especially TIG and MIG welding)

Resistance welding (especially spot and projection welding)

Laser welding

Robotic welding is suitable for many types of components as well, including sheet metal, tubes, simple or complex shapes, and those made from aluminum or mild or stainless steel.

It’s also possible to program the power supply and robotic arm for precise parameters and movements. Because of their ability to repeat the same work instructions over and over, robotic welding is efficient and greatly reduces common defects like porosity, brittleness, cracking, slag inclusions, burn through, distortion, incomplete fusion or penetration, undercutting or overlapping, or poor aesthetics.

Who Uses Robotic Welding?

Welding is one of the most popular applications for robots in manufacturing. In fact, about half of all manufacturing robots are doing welding work. Typical applications include:

- Automotive parts: engine, exhaust, frame, and body components

- Bicycles, lawn and garden equipment

- Construction: tubes, pipes, beams, wire mesh

- Medical equipment

- Furniture, shelving, cabinets

- Industrial equipment

- Appliances

Chances are your welding application can be automated, too.

What Kind of Robotic Welding System Do I Need?

No two systems are identical and there are many options when it comes to equipment, sensors, and safety mechanisms. But there are common types of equipment that go into most.

At Force Design, we build turnkey welding systems that are comprehensive for your process – not merely a robotic arm with a torch.

Most importantly, because our team has years of experience with both robotics and welding, including common defects and critical parameters, we can select the right equipment for your needs. That means you can focus on the welding process and we’ll “translate” it into an automated system with exactly the components you need and none that you don’t.

- Welding power supply

- Power cables, supply lines, and tanks for shielding gas, wire feeders

- Multi-axes robotic arm

- Torch, electrodes, or laser depending on the type of welding

- Peripheral equipment

- Wire cutter to trim excess wire

- Nozzle cleaning station/reamer

- Torch changing station

- Coatings and covers to protect cables, tools, and parts from excess spatter

- Fixtures to secure weldments (e.g., manual, pneumatic, and changeout)

- Safety equipment (e.g., gates, interlocking switches, keyed lock systems, safety mats, light curtains, scanners)

- On-board sensors and cameras

- Collision avoidance

- Seam finding for weld placement

- Tool center point (TCP) detection for weld placement sensors for proper weld

- Verification of clamp and part position

- Software for data collection (e.g., consumable use, monitoring critical parameters, production analytics)

Adding Value Now and in the Future

You’ll get more than just high-quality welding from an automated system. We offer capabilities that bring extra value so you can optimize bigger picture efficiency, too. For example:

Connected, computerized systems relay real time data via graphical user interface (GUI) for easy access. So whether you want to track productivity patterns or just better anticipate supply needs, you’ll know what’s going on in more detail.

Many custom systems can also be expanded or integrated with other workstations or processes as your needs change. Some options include robots for precision component preparation (such as cutting or bending), post-weld finishing processes, quality inspection, end-of-line packaging and more.

If you anticipate growing your welding operations in the future, your weld cell can be built with space for additional robots, duplicate systems, and additional tooling.

Let’s Get to Work!

1

Connect With Us

Work with our team to create an automation strategy that’s right for you.

2

Get Customized Automation

Have the equipment you need to meet your goals.

3

Do Great Work

Reach your manufacturing goals with the right equipment and ongoing support.

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.