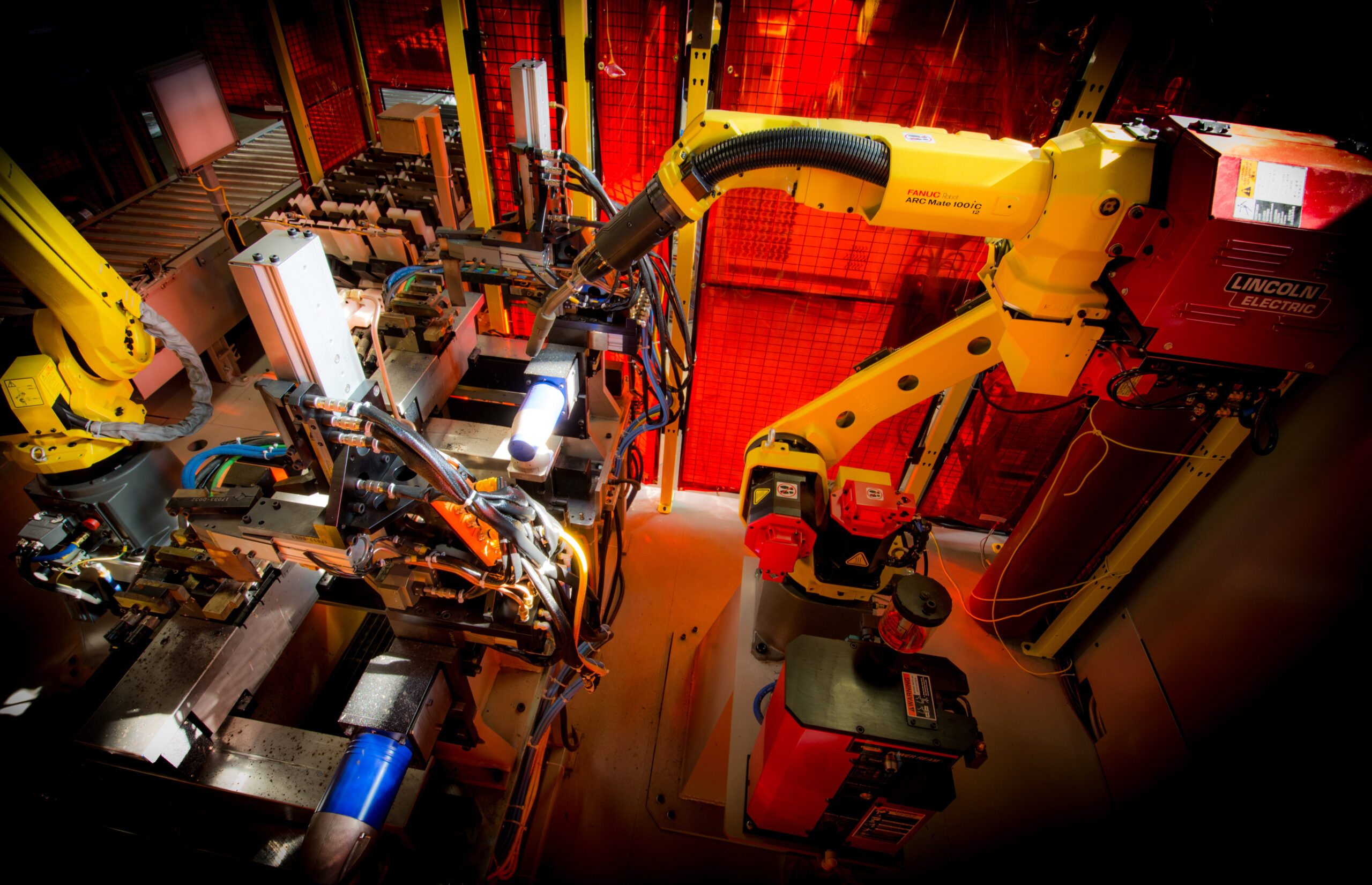

This automated welding cell utilizes a MIG robot, nut welder, and material handling robot. It is designed to accommodate 53 different model numbers of welded components and can run for one hour unattended.

- Infeed conveyors are loaded by the operator and then the equipment runs automatically until emptied.

- The operator selects the model number to weld by scanning a work order.

- All tooling is servo controlled and automatically adjust to accommodate changeover. No operator assistance is needed for changeover.

- A vision camera is used to confirm that the correct parts are loaded in the correct orientation.

- Completed parts are placed on an exit conveyor and dropped into a parts bin outside the cell.