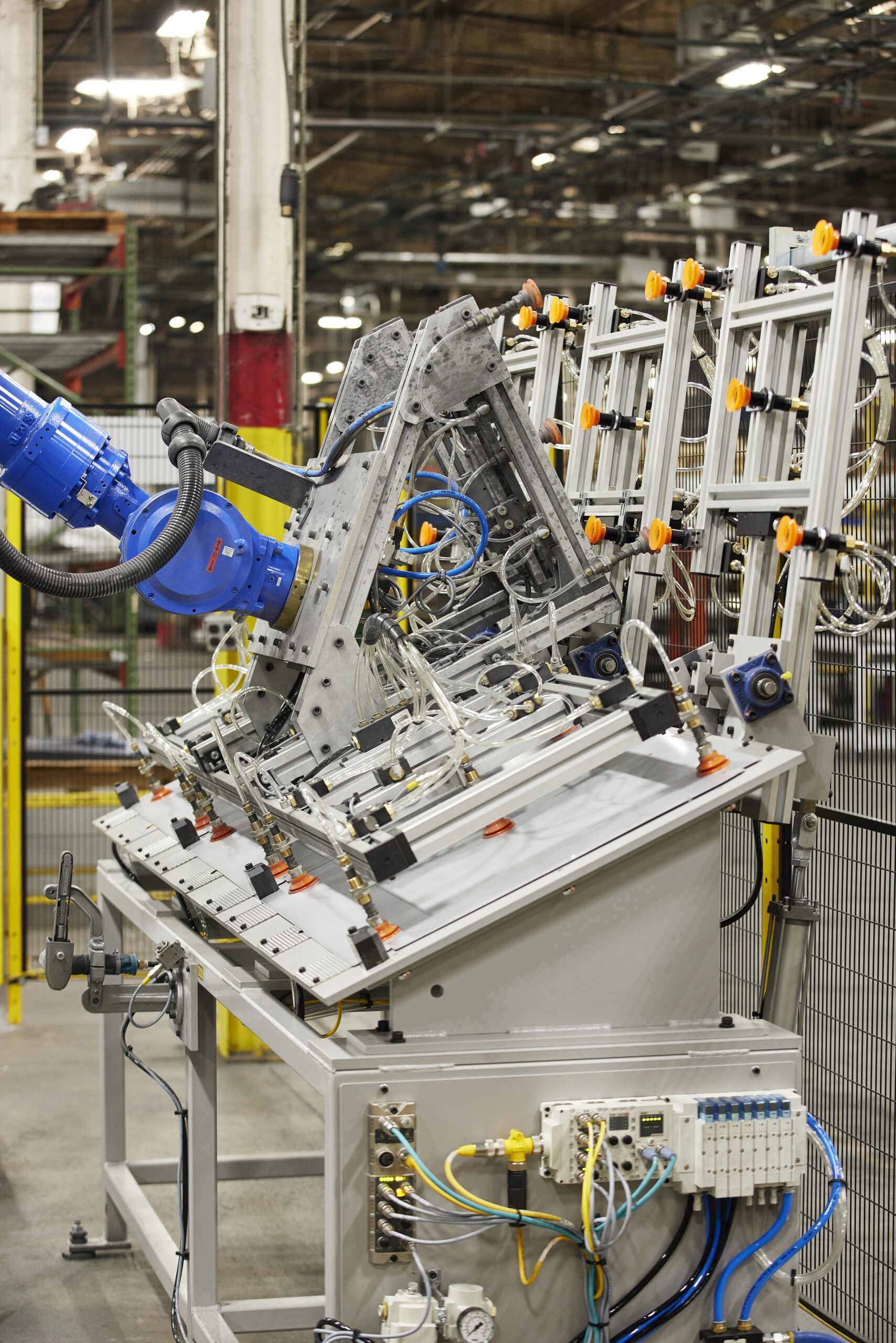

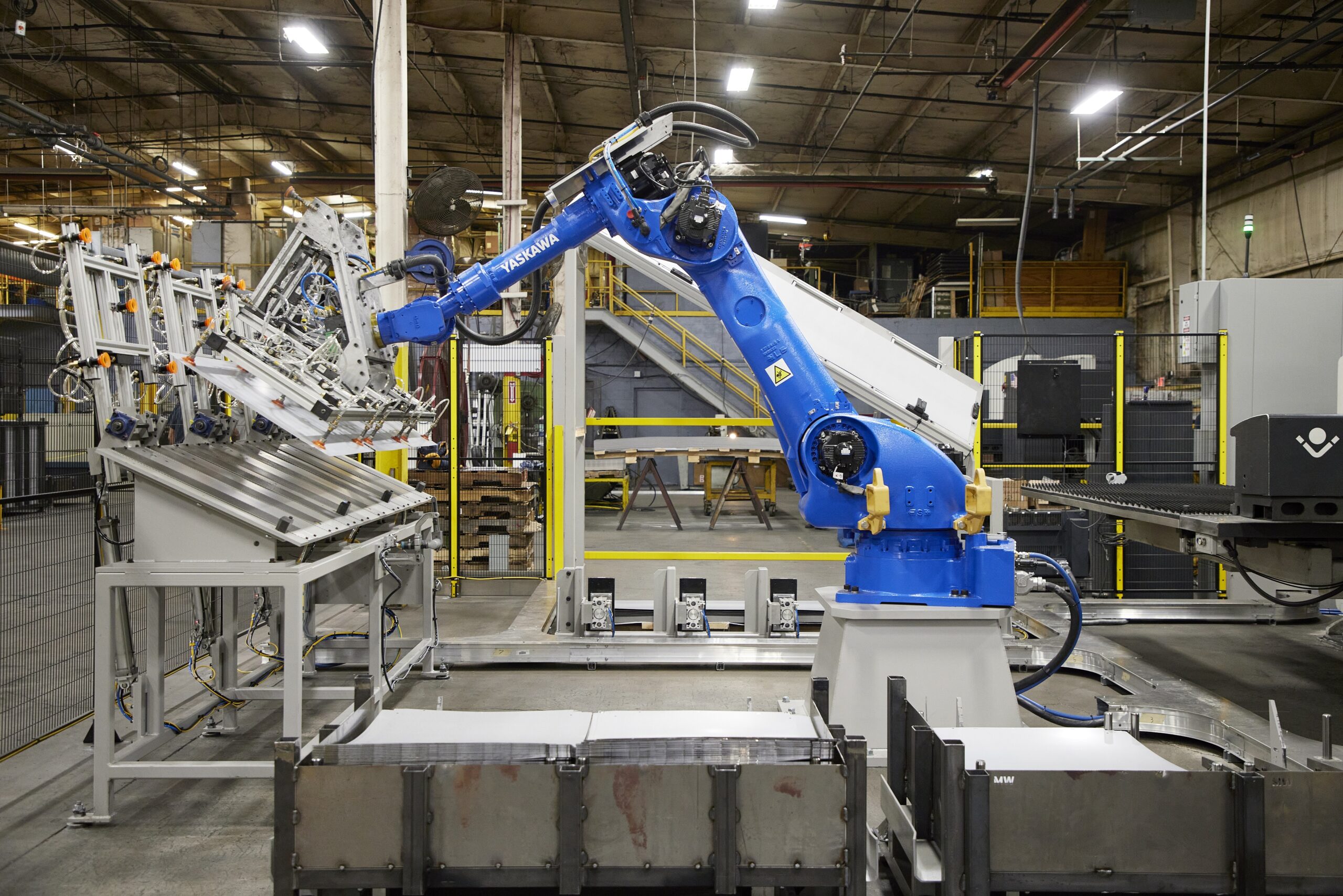

This robotic system picks steel sheets from a pallet, tends a punch press, and deburs and stacks the completed parts. The only operator interaction needed is to provide raw material and remove completed parts a few times per day. This system increases efficiency, quality, and throughput while allowing personnel to work on more preferred tasks.

MAJOR COMPONENTS USED:

Allen-Bradley – Controls System

Yaskawa – Robot

Dynabrade – Sanding Tool

Industrial Magnetics – Fanner Magnets

Piab – Vacuum

Reiku – Robot cable management

SMC – Pneumatics

Robotunits – Extruded Aluminum Structures

SA Tech – Guarding

ABOUT THIS PROJECT:

- Deburring

- Consumer Products

- Machine Tending

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.